10kw Hydro Turbine

| XJ30-10DCT4-Z | |

| 10000 watt | |

| 30 – 38 Meters | |

| 40 – 50 (l/s) |

- Technical Specifications

- Packing List

- About Micro Hydro Power

- Contact Us Now

| Main Parameters of 10kw Hydro Turbine | ||||

| No. | Items | Parameters | Remarks | |

| 1 | Model | XJ30-10DCT4-Z | Single Nozzle

Turgo Turbine |

|

| 2 | Rated Head | 30–38 | (meters) | |

| 3 | Rated Flow | 40–50 | (l/s) | |

| 4 | Output | 10000 | (W) | |

| 5 | Efficiency | 70 | (%) | |

| 6 | Pipe Diameter | 200-250 | (mm) | |

| Generator | ||||

| No. | Items | Parameters | Remarks | |

| 1 | Model | SF10.0-4 | Permanent Magnet Generator | |

| 2 | Style | PMG | ||

| 3 | Output | 10000 | (W) | |

| 4 | Voltage | 230 or 110 | (V) | |

| 5 | Current | 43.47 | (A) | |

| 6 | Frequency | 50 or 60 | (HZ) | |

| 7 | Rotary Speed | 1500 | (RPM) | |

| 8 | Phase | Single | (Phase) | |

| 9 | Power Factor | 1.0 | ||

| 10 | Altitude | ≤3000 | (meters) | |

| 11 | Insulation Grade | B / B | ||

| 12 | Protection Grade | IP44 | ||

| 13 | Temperature | -25~+50 | ℃ | |

| 14 | Relative Humidity | ≤90 | % | |

| Control Box / Control Panel | ||||

| No. | Items | Parameters | Remarks | |

| 1 | Model | WY10-1 | ||

| 2 | Safety Protection | Short circuit Protection | ||

| 3 | Insulation Protection | |||

| 4 | Over Load Protection | |||

| 5 | Grounding Fault Protection | |||

| Packing | ||||

| No. | Items | Parameters | Remarks | |

| 1 | Packing Material | Fiberboard | ||

| 2 | Packing Size | 85×65×85 | (CM) | |

| 4 | Gross Weight | 269 | (KGS) | |

| NO. | Name | Picture | Quantity | G.S. |

| 1 | Micro-hydro Turbine Generator unit |  |

1 | Set |

| 2 | Butterfly Valve |  |

1 | Set |

| 3 | Reducer Pipe |  |

1 | Set |

| 4 | Expansion Bend |  |

1 | Set |

| 5 | Load for Constant Voltage Regulator |  |

1 | Set |

| 6 | Asbestos Pad |  |

2 | Set |

| 7 | Foot Screw |  |

4 | Set |

| 8 | Butterfly Valve Screw |  |

8 | Set |

| 9 | Expansion Bend Screw |  |

8 | Set |

| 10 | Grease lubricant |  |

1 | Set |

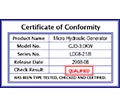

| 11 | Certification |  |

1 | Copy |

| 12 | English Version User Guide | 1 | Copy | |

| 13 | Installation Dimension Chart | 1 | Copy |

About Micro Hydro Power

Micro-hydro schemes extract energy from water flowing downhill, without the need for large dams. A range of turbines can be used, depending on the rate of flow and the head available (i.e. the height the water is falling). In addition to the turbine, civil works are required to divert water from a stream into the turbine, and return it to the stream afterwards.

The power from the turbine is delivered through a rotating shaft, which can be used to drive machinery directly, or can drive a generator to produce electricity. Micro-hydro schemes are often in off-grid areas, so any electricity produced is often used in a ‘mini grid’ for a village or town, selling power to households and businesses. The income is used to pay for operation and maintenance of the scheme, and sometimes to pay back a loan used to fund the construction.

Micro-hydro is cheap to operate, but capital-intensive to install, so a subsidy is often required, unless loans are available of favorable terms.

Micro-hydro brings environmental benefits through avoiding the use of fossil fuels and by not using large dams, with their associated flooding of land. For an off-grid community, the benefits of a reliable electricity supply are significant, including refrigeration, communications, lighting, computers and the ability to run machinery. In many cases the availability of electricity allows new profitable businesses to be started, helping to pay for the micro-hydro scheme.

Micro-hydro schemes are popular in mountainous areas, with the Himalayas and Andes having large numbers of schemes, although they are also present in hilly areas in many countries. Micro-hydro schemes are also present in developed countries, where they are usually grid connected.

Technology background

When water flows from a higher to a lower point, potential energy is released. Micro-hydro schemes were developed to extract this energy in the form of mechanical power. The amount of power available depends on the volume of water flowing and the height (head) from which it drops. Micro-hydro technology can only be used in wet mountainous areas, as it depends on adapting existing streams rather than making large dams to manage water flow. A micro-hydro scheme consists of a turbine, civil works and optional equipment for generating electricity.

Turbines

Turbine design varies depending on the head and flow of the available water:

— Pelton turbines consist of a set of small buckets arranged around a wheel onto which one or more jets of water are directed. These turbines work well with a high head and do not require a large flow.

— Francis turbines have a spiral casing that directs the water flow through vanes on a rotor and is used with lower heads and higher flows.

— Cross-flow or Banki turbines are made as a series of curved blades fixed between the perimeters of two disks to make a cylinder. The water flows in at one side of the cylinder and out of the other, driving the blades around. They are used at even lower heads and larger flows, and are much easier to make than most other designs.

— Propeller turbines are used for very low heads and large flows. The blades can be fixed, similar to a boat propeller, or a more complex version, the Kaplan turbine, has blades that can be adjusted in pitch relative to the flow.

— River current turbines can be used with a large flow in a river. They are similar to a wind turbine, but immersed in flowing water rather than air.

Civil works

In addition to the turbine, a system needs civil works to get the water to the power house in which the turbine is installed.

A small dam is required in the stream bed to direct the water to the ‘head works’. Most micro-hydro systems are ‘run-of-river’ i.e. they store very little water behind the dam. The head works usually consist of a settling tank, to remove silt from the water. This feeds either a canal or a pipe that transfers water to the fore bay, another tank sited above the power house. The canal or pipe can be fairly long, 1 km or more, if a suitable stream is distant from where the power is required.

The forebay usually has a second settling tank and a screen to prevent silt and floating debris entering a pipe called the penstock, which is made as steep as possible to transfer water to the turbine. When the water leaves the turbine, it flows back to the stream through the tailrace. Some turbines, such as the Francis and propeller turbines, can use a diffuser (also known as a draft tube) in the outlet pipe to increase performance by reducing the kinetic energy of the water leaving the system.

Generating electricity

When turbines are used to generate electricity the output from the turbine must match the demand for power, otherwise the voltage and frequency can vary suddenly, which can badly affect electrical equipment. The demand for electricity in an off-grid system is often very variable, because people switch lights and machines on and off, so the power supply must be varied to keep close control. There are several ways to do this.

One approach is to use a mechanical governor, which controls the water-flow to the turbine by opening and closing valves. However, these are expensive and react slowly. The alternative is to use an electronic load controller, which allows the full flow of water to run the turbine, but switches a ‘dump load’ on and off to balance the varying power demand. The dump load is usually an electric heater which can simply be cooled by the flowing water, or if possible used to generate useful heat, such as for washing water.

Installation and economics

The term ‘micro-hydro’ is usually used for power outputs of between 5 kW and 100 kW. This is sufficient to give light to a village or a small town or to run one or more small industries, such as wood or metal working machines. Internationally, most micro-hydro systems are off-grid, as they are usually in remote mountainous areas. Systems below 5 kW are usually termed ‘pico-hydro’ and are usually used for individual homes or communities of two or three houses.

When a micro-hydro system is installed in a community, the local people are usually involved, as labour is required to build the civil works. This labour is regarded as providing about 15% of the total cost of a system and is sometimes referred to as ‘sweat equity’. Most micro-hydro systems require subsidy, as the capital cost is fairly high (about £2,000 per installed kW), while the running cost is comparatively low. Systems requiring a large amount of civil work or sited in inaccessible areas can cost much more. People pay for the electricity provided or for the service available from machines driven by mechanical power. This income is usually used to pay for operation and maintenance of the plant, but may be sufficient to pay back a loan, if one is taken to cover part of the cost of installing the plant.

Benefits

The output from a micro-hydro system is shaft power. This is often harnessed to drive a generator for electricity, but it can also be used to drive machinery directly. Many successful micro-hydro programmes have used shaft power to run food processing equipment, such as grain mills, rice hullers and oil expellers. Most people see the main benefit of electricity as providing lighting, but this is only required in the evening, about four hours a day, while the power is available over 24 hours. Programmes that encourage the use of electricity to run small industries are much more likely to be successful.

The main environmental benefit of micro-hydro is the replacement of fossil fuels, such as diesel for driving machinery and generating electricity, or kerosene for lighting. There are positive benefits for remote communities using micro-hydro electric systems, such as refrigeration for health clinics, computers and radio for schools, internet access and mobile phone charging. Young people are drawn back to their rural communities, as they can use their education to run small businesses powered by electricity. A major attraction is the availability of entertainment, such as TV and videos.

Environmental impact of hydro power

Globally, hydro-power is the largest source of renewable electricity, providing about 16% of the world’s electricity (global supply was 3,040 TWh in 2006), but most of this is from large-scale systems. In 1995, the total micro-hydro capacity in the world was estimated at 28 GW, supplying about 115 TWh of electricity. About 40% of the micro-hydro capacity was in developing countries. There are concerns about the environmental impact of large-scale hydro, because it requires large areas to be flooded to provide reservoirs, and can have serious impact on water management. Carefully-designed micro-hydro systems take a limited amount of water from a river or stream, have a small storage volume, and return the water a short distance down stream, and thus have very little environmental impact. Large numbers of small hydro systems have much less environmental impact than a single large hydro scheme supplying the same energy output.

Use in developing countries

The main micro-hydro programmers in the developing world are in mountainous countries, such as Nepal (around 2,000 schemes, including both mechanical and electrical power generation) and other countries in the Himalayas. In South America, there are micro-hydro programmes in the countries along the Andes, such as Peru and Bolivia. Smaller programmes have been set up in hilly areas of Sri Lanka, the Philippines, China and elsewhere in the world. Most of the systems that run electric generators supply mini-grids that distribute power around a small town or village. Transformers are often used to increase the voltage in order to reduce transmission losses if the cable has to run distances of more than 1 km. These systems can often be linked to the main national grid if it is subsequently extended to include an area that already has a micro-hydro station.

Use in developed countries

Although micro-hydro systems were used in the Europe and the USA from the end of the 19th century, most were abandoned as grid power became available, but their potential is now recognized. Germany has many plants set up along small rivers, usually on sites which were previously used for water mills. Owners of old water mill sites in the UK are beginning to see the possibilities of micro-hydro systems and a steadily growing number are being installed for local electricity production. The advantage of old mill sites is that they already have civil works that can be upgraded and adapted for use with turbines. Most micro-hydro systems in developed countries are grid connected.

Introduction to Micro-Hydro

Micro hydro refers to hydro power systems with a power rating of 100kW or less. A 100kW system will produce 100 standard units of electricity in one hour. Micro hydro systems differ from large hydro power since the flows of water required are much smaller.

Micro hydro systems have been popular in some less-developed countries for a number of years enabling rural communities to enjoy the benefits of electrification in areas with hydro power potential but without a grid network. New technology, less stringent regulation of grid-connected micro hydro generators and standardised turbine designs are now encouraging more widespread interest in micro hydro in the UK.

What are the Benefits?

• The considerable benefits of micro hydro power include the following:

• ‘Fuel-free’ source of power

• Different to large hydro since environmental impacts of installation are negligible.

• Renewable energy source therefore helping to reduce greenhouse gas emissions and having a net positive impact on the environment.

• Constant generation over long periods unlike wind and solar power

• Good correlation with demand (more hydro energy is available in winter when heating loads are high)

• Long lifetime of systems, typically 25 years or more Low maintenance requirements and running costs

• Reasonable payback for grid -connected systems, often 10 years or less

Where can it be installed?

There are three main types of sites which are particularly worthy of consideration for development:

• Historic Water Mills Water was once used extensively as a source of motive power in the British Isles. Some estimates put the number of old mill sites in the UK as high as 20,000. Government targets for renewable energy and the development of modern, small-scale turbine units now make re-activation of many of these old sites for electricity generation economically worthwhile. A major advantage of these sites is that it is often possible to reuse some of the existing civil structures such as the weir and the leat, thereby reducing the cost of the installation.

• Hilly Areas with Spring-Fed Streams In addition to historic sites, considerable potential exists in many hilly areas of Britain for micro hydro power. Turbines are available which can utilise quite small spring fed streams for power generation if the fall is sufficient. These sites can often be developed at reasonable cost since civil structures associated with large flows of water, such as weirs , are not required.

• Weirs. The UK’s rivers have between them 1,000’s of weirs not linked to mill facility, and many of these could be relatively converted to power generation using Hydro Generation’s low cost modular turbine system.

Please visit our other Micro Hydro Hydro web pages for further information on estimating your potential, feasibility studies, abstraction licensing, system design and installation.